IndustryFusion Ready

IndustryFusion Ready

Products marked with the IndustryFusion Ready logo can be digitally networked with the IndustryFusion-X open source networking solution across all manufacturers according to the criteria of Industry 4.0 and offer a wide range of benefits. For example, completely new possibilities in the area of machine financing, transparency across all important production KPIs or innovative production sharing models with which unused capacities can be marketed profitably.

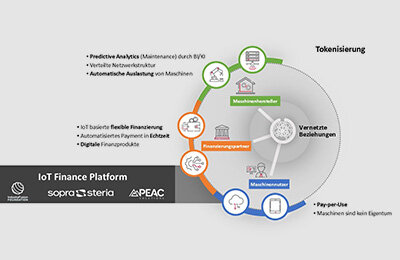

Equipment-as-a-Service (EaaS) is an innovative financing model that makes it possible to rent machines to end users and determine regular payments based on actual usage time. This means that high capital commitments can be avoided, but at the same time modern and energy-saving machines can be used. Further information on how this PEAC Solutions financing model works and a configurator can be found on our partner's website Sopra Steria.

To the configuratorERP for manufacturing: Make better decisions!

IndustryFusion-X enables simple and secure access to all data generated in production thanks to a standardized infrastructure and standardized formats. Transparent production planning makes it possible to identify optimization potential. Data from production machines and workstations is analyzed, assigned and stored in the right context. This allows good decisions to be made immediately. Find out more on the website of our partner Monitor ERP!

Fully automated quotation processes enable production sharing!

IndustryFusion-X enables new horizontal value creation networks such as cloud manufacturing, production and resource sharing. This allows production facilities used in manufacturing to be optimally utilized. The basic prerequisite for this is a digital twin of the production plant, which enables an assessment of production possibilities and capacities and, on this basis, an automatic calculation of manufacturing costs. IndustryFusion-X and corresponding software tools make it possible to connect your production to these networks. Further information can be found on the website of our partner goCAD.

FAQ IndustryFusion Ready

What does IndustryFusion Ready stand for?

The IndustryFusion Ready logo (IF Ready for short) was introduced by the IndustryFusion Foundation in 2022 to give manufacturers the opportunity to label their Industry 4.0-capable assets. Both machines and software systems and their licences can represent an asset. Assets that fulfill the Industry 4.0 criteria are labelled IF Ready. The IF Ready logo stands for the fulfillment of minimum requirements with regard to the availability of standardized semantic data & parameters, functions and globally unique identifiability.

How can I get the IndustryFusion Ready logo for my product?

In order to receive the IF Ready logo, the assets must undergo a verification process set up by the IndustryFusion Foundation. Once the verification process has been completed, the asset must be registered with the IndustryFusion Corporation for Identification and Certification (IFRIC.org) in order to make the asset globally identifiable with a unique IF ID. Once the IF-ID has been assigned, the asset is IF Ready and may be labelled with the logo.

What added value do IndustryFusion Ready products offer?

In addition to indicating that cross-manufacturer networking is easy to implement, the logo provides information about the applicability of the labelled products for new business models and digital services such as predictive maintenance, but also Production Sharing or Equipment-as-a-Service.