Smart machine

Challenges

Modern production machines measure a large amount of data during the production process and store a small part of it in a cloud or locally. In order to use the data for further optimisation, a high level of individual implementation effort is necessary. The basis would be a standardisation of data in order to be able to apply developed modules and models in a generalised way.

Solution with IndustryFusion

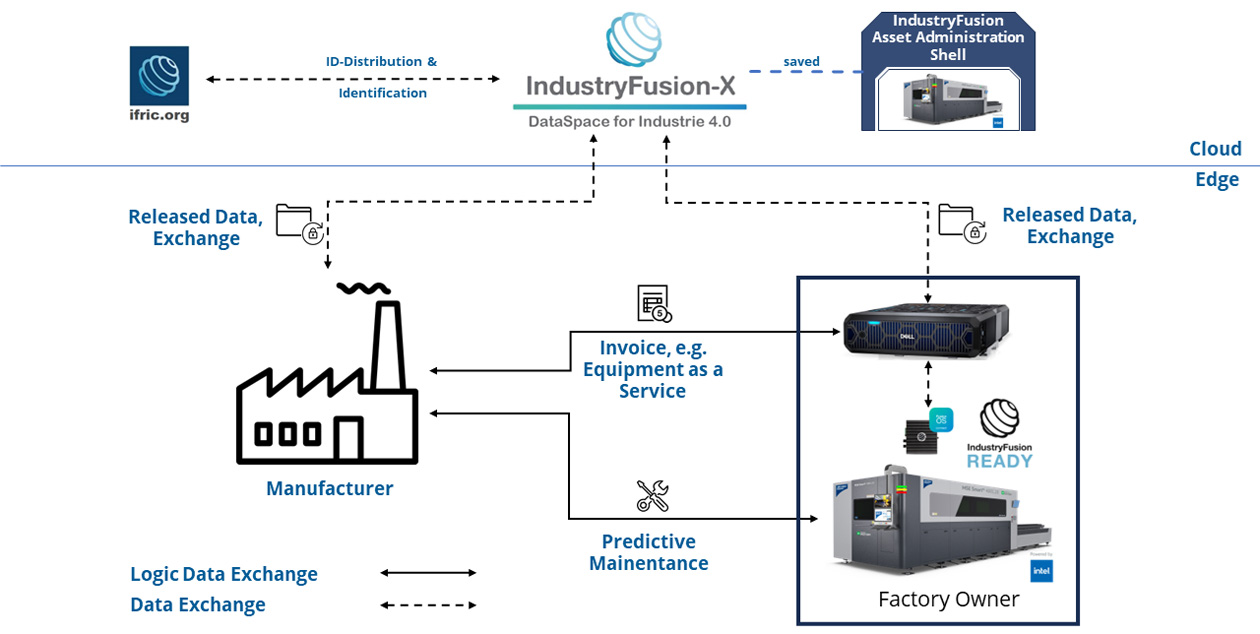

IndustryFusion-X provides this standardisation of data for machines or machine types and at the same time creates the connection to a cloud-based data room for machine manufacturers and factory operators. The communication standardisation makes it possible to apply manufacturer-independent analysis models, e.g. for optimisation through artificial intelligence. This standardisation is achieved by connecting the Factory Server. The machines are linked to it via Smartboxes and standardised data communication begins there, all the way to the data-based cloud.

Benefits

The machine manufacturer can use this available data in the cloud to plan predictive maintenance or optimise production processes through AI. All areas increase the availability of the machine and at the same time increase economic efficiency. In addition, this data flow offers the possibility of using new machines as part of Equipment-as-a-Service and thus avoiding a high capital commitment for new machines.