Smart filter cartridge

Challenges

The replacement of filter cartridges used in extraction systems is normally carried out cyclically based on a previously defined installation period without taking into account the actual usage time and the associated contamination in the cartridge. For economic reasons, it makes sense to use filter cartridges in a resource-saving manner and to select the degree of contamination as the basic decision factor for the time of replacement. For the filter cartridges used so far, it is not possible to trace the metal particle contamination under which they were in use and thus to determine the degree of contamination.

Solution with IndustryFusion

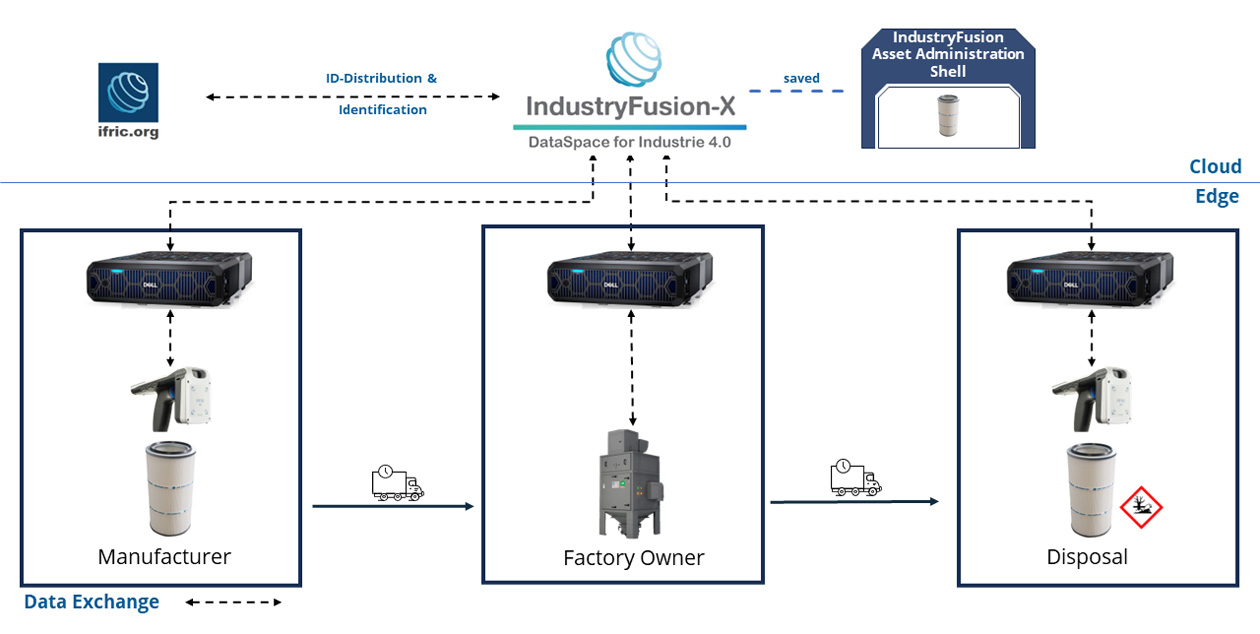

Every company, whether manufacturer or factory operator, has its own Factory Server. The Factory Server is connected at the edge level with the individual machines and electrical devices such as an RFID reader (coloured frame). A network of different companies is created via IndustryFusion-X as a cloud-based data room and the connection to the Factory Server. The example of the filter cartridge as an asset has a digital twin in the cloud, whose unique identification is made by an ID assigned by the IFRIC. Each company can retrieve the associated data or add corresponding data on production, use or disposal. This means that all relevant data is available to all stakeholders without any barriers.

Benefits

The machining processes are precisely traceable via the globally unique identification of the filter cartridge and the link to the processing machine used via IndustryFusion-X. At the same time, ideal resource-saving exchange points can be determined via the cleaning times, their frequency and the resources required for them. At the same time, ideal, resource-saving replacement points can be determined via the cleaning times, their frequency and the resources required for this. The globally unique identification allows a suitable disposal for the filter cartridge depending on the contamination with certain metal particles. At the same time, proper disposal can be assigned to the respective filter cartridge, thus providing evidence for official requirements. At the same time, the identification ensures the use of certified products and thus an increase in occupational safety.